Maximizing the Value of Free Warehouse Storage Periods

Imagine you just scored some amazing deals from China using Fishgoo. Now your items wait safely in the warehouse, and you get 100 days of free storage. That sounds great, right? By maximizing free storage, you can group parcels, save on shipping, and keep your costs low. Warehouse optimization helps you use every inch of space and time wisely. If you plan well, your shopping stays stress-free and your packages arrive just when you want them.

Key Takeaways

Make the most of free storage by putting items together. This helps you spend less on shipping and keeps costs down.

Think ahead about when your inventory will come. Use tracking tools to see when items get there and pick the best shipping times.

Keep your warehouse neat and organized. Use clear labels and sort items smartly to pick orders faster and make fewer mistakes.

Try using tall shelves to save space. Stacking things higher lets you store more without needing a bigger warehouse.

Check how much storage you use often. Watching this helps you skip extra fees and plan shipments well.

Understanding Free Storage Periods

What Is Free Storage?

Free storage lets you keep your things in a warehouse for a certain time without paying more money. For example, Fishgoo gives you 100 days to store your stuff for free. This time helps you gather items from different sellers and send them together. You can choose when to ship your things and do not have to pay for storage right away. Free storage is very helpful if you shop from other countries or buy from many places.

Key Terms and Conditions

You should learn the main rules before using free storage. Each warehouse has its own rules, but these are some common ones:

Storage space is counted in square meters. Some warehouses want you to use a minimum space.

You might need to pay a security deposit, usually for three months.

There can be handling charges when you bring goods in or take them out.

You must get insurance for your goods. The warehouse only covers the building and workers, not your items.

Storage fees and payment rules are written in your contract.

You have certain times and rights to access your goods. Some warehouses charge more if you need special access.

Fishgoo makes it easy. You get 100 days of free storage, and you can pay a small fee to keep your items longer. This helps you use the warehouse better and save money.

Why Maximizing Free Storage Matters

If you use free storage well, you save money and use the warehouse better. If you leave things too long, you may pay extra fees or run out of space. Here is what can happen if you do not plan:

Financial Consequence | Description |

|---|---|

You pay more if you keep too many things in storage. | |

Tied-up cash flow | Your money is stuck in things you have not sold. |

Diminished product value over time | Items lose value if they stay too long. |

Low or zero-profit sales | You might sell for less just to make space. |

Inefficient work environment | Crowded shelves make work slower for your team. |

Warehouse optimization helps you stop these problems. You keep your supply chain working well and lower the chance of problems. By using free storage the best way, you make the warehouse help you instead of causing trouble.

Preparing for Warehouse Optimization

To get the most from your free storage, you need to plan. Each step should help with warehouse optimization. If you plan early, you will not feel rushed later. Your items will move easily from buying to shipping.

Planning Inventory Arrivals

You must know when your products will get to the warehouse. This helps you use your free storage days well. Fishgoo’s tracking and notifications show updates right away. You can see when each item gets there and pick the best time to ship. Inventory planning software makes this job easier. Here are some helpful tools:

Tool Type | Benefits |

|---|---|

Finds weak spots in your supply chain and improves workflows. | |

Demand Forecasting Apps | Predicts how much stock you need and helps avoid shortages or extra inventory. |

Inventory Optimization Apps | Makes sure products move in and out of the warehouse efficiently. |

Inventory forecasting helps you guess what you’ll need by looking at old data. This helps you stop having too much or too little stock. It keeps your warehouse optimization working well.

Coordinating with Suppliers

Working with suppliers is important for warehouse optimization. You can share inventory data so they know when to send more. Some companies use vendor-managed inventory programs. These let suppliers help watch and refill products. This teamwork means you get the right items at the right time. You do not waste space or money. Good supplier relationships also mean better deals and more on-time deliveries.

Vendor-managed inventory programs help teams work together.

Sharing data lets suppliers send stock when you need it.

Strategic sourcing saves money and makes deliveries better.

Setting Storage Goals

Clear goals help you see if your warehouse optimization is working. You want to use all your space and keep things moving. Here is one simple metric to check:

Metric | Description |

|---|---|

Shows how much space you use compared to what’s available. |

You should also check key performance indicators to find ways to get better. When you look at your warehouse capacity and turnover rates, you can set goals that fit your business. This keeps your warehouse running well and helps your optimization plan.

Tip: Check your storage goals every month. Change them if your business grows or changes.

Organizing Inventory for Maximum Efficiency

A tidy warehouse helps everything work better. Good warehouse organization makes each step easier. This starts when goods arrive and ends when they ship out. Here are ways to make your inventory management strong.

Inventory Audits and QC Photos

You should find mistakes before they get big. Regular inventory audits help you spot and fix errors fast. This keeps your records right. Fishgoo gives you free QC photos for every item. These photos help you check if the product is good. You can also see if you got what you ordered.

Fix inventory mistakes early to keep things correct.

Make rules for your team and train them well.

Use good software and hardware, and update them often.

Keep your warehouse neat and safe for everyone.

Look at your inventory data often to catch problems.

Tip: Check how you pick items and watch important numbers. This helps you find ways to get better. It is a big help for optimization.

Categorizing and Labeling

Clear labels and smart sorting are very important. When you label every item and shelf, you make fewer mistakes. This also makes picking orders faster. Scanning tools help you collect data quickly. They also stop mistakes from typing by hand.

System | Description | Impact |

|---|---|---|

Micro-Zoning | Split space into small picking zones | Shorter walks and fewer mistakes |

Cluster Picking | Group similar items together | More orders finished in less time |

Serialization | Give each item its own special code | No mix-ups and better tracking |

Real-Time Feedback | Watch picker work right away | Fewer mistakes and more responsibility |

Warehouse organization ideas like these help you keep things in order. You will have fewer mistakes and customers will be happier.

FIFO/LIFO Systems

Picking the right way to move stock is important. FIFO means First-In, First-Out. It works best for things that can go bad, like food. You use the oldest stock first so nothing gets wasted. LIFO means Last-In, First-Out. It is good for things that do not expire. You move the newest items first. This can help you make more money if prices change.

FIFO keeps your stock fresh and stops waste.

LIFO can help you earn more with some items.

LIFO might lower your taxes but can make records harder to read.

When you choose the best system, your warehouse works better. This helps your whole optimization plan.

Maximizing Warehouse Storage Capacity

You want to use every bit of space in your warehouse. Smart warehouse optimization lets you store more and work faster. It also helps you save money. Here are some good ways to get more floor space and boost storage capacity.

Vertical Storage Solutions

Many warehouses have empty space above the shelves. You can use vertical storage to fill this space. Stacking items higher and using tall shelves helps you store more. You do not need a bigger building.

Most U.S. warehouses have up to 50% unused vertical space.

Using vertical storage can make things 40% more efficient.

Case Study: XYZ Logistics got 35% more storage by going vertical.

You can add mezzanine floors or tall racks. Automated vertical lifts help too. These changes let you store more in the same area. Vertical storage keeps your warehouse neat and organized. Fishgoo’s consolidation service helps by combining your items. This way, you use less floor space and more height.

Tip: Always check shelf weight limits before stacking higher. Safety is very important!

Creative Racking and Shelving

You can set up racks and shelves in smart ways. This is a big part of warehouse optimization. Here are some ideas that work well:

Mobile shelves save up to 80% of space by removing fixed aisles. These are great for small warehouses.

Adjustable racks give you flexibility. You can change them as your inventory changes.

Mix storage density with product selectivity. Think about how many SKUs you have and how often you move them.

Arrange racks to use the full length of your warehouse. This gives you more floor space and faster picking.

Fishgoo’s packaging services help you save space too. You can use vacuum packaging or strong boxes to fit more items. Packing tightly means less wasted space and easier shipping.

Best Practice | Description |

|---|---|

Leverage warehouse consolidation | Combine orders in one place to cut handling and transport costs. |

Centralize product storage | Store all items together to avoid split shipments. |

Utilize vertical storage solutions | Use the full height of your warehouse to store more inventory. |

Reduce inventory handling | Fewer moves mean less work and lower costs. |

Layout Optimization

How you set up your warehouse matters a lot. Good optimization means you use every part of your warehouse well. Group similar products together. Put popular items near the shipping area. This cuts walking time and helps your team work faster.

A good layout keeps your warehouse safe and easy to use. Check your setup often to find problems and make changes as you grow. Here’s what layout optimization can do:

Impact Area | Evidence |

|---|---|

Improved Space Utilization | Better aisles can give you up to 30% more storage space. |

Enhanced Productivity | Good pick paths can cut travel time by up to 50%. |

Reduced Operational Costs | Smart layouts can lower labor costs by 15-20%. |

Increased Safety | Good layouts can cut workplace accidents by up to 40%. |

Better Inventory Management | Better visibility can lower holding costs by up to 25%. |

Real-world example: ABC Fulfillment Center picked 25 more orders per hour.

GHI Warehouse had 30% fewer injuries after layout changes.

Fishgoo’s warehouse tools help you track inventory and review your layout. Their dashboard shows where you can improve. If you check your setup often, your warehouse will run smoothly and safely.

Note: Try to check your warehouse layout every few months. Small changes can make a big difference in storage and workflow.

By using vertical storage, smart racking, and good layout, you get more floor space. Your warehouse works better for you. These steps help you store more, save money, and keep your team happy.

Streamlining Receiving and Shipping

Efficient Receiving Processes

You want your warehouse to work well when new goods come in. Check all your paperwork before shipments arrive. This helps you find problems early. When items get there, unload them with care. Look for any damage right away. Use barcode scanners to check each item. Make sure everything matches your order. Count your goods and move them to the right spot. Update your records as soon as you finish. These steps help your warehouse run better. They also keep your inventory correct. Fishgoo helps by offering parcel consolidation and value-added packaging. Your items stay safe and organized from the start.

Fast Order Turnaround

Shipping orders quickly is good for you and your customers. Fast shipping means less inventory sits in your warehouse. You pay less for storage and skip extra fees. Customers like getting their packages fast. They may buy from you again if you deliver on time. Quick order turnaround makes you stand out from other sellers. Fishgoo lets you group items and use special packaging. This helps you ship faster. It supports your optimization goals and keeps delivery speed high.

Tip: Happy customers come back and tell friends about your service.

Reducing Dwell Time

You can make goods leave your warehouse faster with smart scheduling. Book dock slots early to stop traffic jams. Use dashboards to see what is happening and fix delays. Digital forms make check-ins quick. Flexible rules help you use space better. If you have more than one warehouse, match schedules to keep things moving. Try dynamic slotting and cross-docking to move goods out fast. These ideas are important for optimization. They help you avoid paying for extra storage. When you cut dwell time, your warehouse works better and your business runs smoothly.

Leveraging Technology for Warehouse Efficiency

Real-Time Inventory Tracking

It is important to always know what is in your warehouse. Real-time inventory tracking helps you do this. When you use a warehouse inventory management system, you get updates right away. You see when items come in, move, or ship out. This helps you keep your stock levels correct and avoid mistakes. You can use barcode scanners, mobile apps, and live dashboards to watch your inventory.

Here are some ways real-time tracking helps your warehouse:

You always know how much stock you have, so you can act fast if you need more.

The system tracks items for you, so there are fewer mistakes and less work for people.

You can check your inventory from anywhere, even on your phone.

Barcode scanning helps you find and check items quickly.

You can use the information to decide what to order next.

Fishgoo’s online dashboard shows your items and sends you alerts right away. This helps you stay in control and keep your warehouse working well.

Automated Alerts and Reminders

Automated alerts help you remember important things. You do not have to keep track of everything by yourself. The warehouse inventory management system sends reminders when stock is low or it is time to order more. This keeps your warehouse running well and stops you from running out of things you need.

Alerts tell you when to restock, so you never forget.

The system can fill out purchase orders for you, which saves time.

Staff can work on bigger jobs instead of checking stock all day.

Automation means fewer mistakes and better records.

With Fishgoo, you get alerts for every step, from when items arrive to when they ship. You always know what is happening in your warehouse.

System Integration

When you connect your warehouse management system to other business tools, everything works better. You can link your warehouse to sales, shipping, and customer service. This makes your business faster and more accurate.

Benefit | Description |

|---|---|

Real-time tracking helps stop over-selling or running out. | |

Efficient order processing | Orders get filled and shipped faster. |

Increased visibility | You can see all your operations in one place. |

Improved accuracy in shipping | Fewer mistakes mean customers are happier. |

Improved customer satisfaction | Customer service can give quick updates on orders. |

Cost control and financial insight | You can spot waste and save money. |

If you have a big warehouse, try connecting your warehouse management system with ERP or CRM tools. This makes your warehouse work better and helps your business grow.

Safety and Workflow Improvements

Clear Pathways and Safety Checks

You want your warehouse to be safe for everyone. Clear pathways help stop trips and falls. If you see a hazard, fix it fast. Safety checks keep things neat and protect your team. Here are some safety steps you can use:

Remove hazards as soon as you find them.

Train your team often and test their skills.

Check equipment and work areas on a schedule.

A clean warehouse helps a lot. Look at this table for more ways to stay safe:

Safety Protocols | Description |

|---|---|

Clean and Organized Work Areas | Tidy spaces help stop slips and falls. |

Proper Training Programs | Training helps everyone know safety rules. |

Material Handling Equipment | Good equipment lowers the chance of injury. |

Ergonomic Practices | Safe lifting and moving protect your team’s health. |

Regular Safety Inspections | Inspections help you find problems early. |

Culture of Safety | When everyone cares about safety, accidents happen less. |

Tip: Make safety part of every day, not just a rule.

Staff Training

Training your team helps your warehouse work better. When people know what to do, work is faster and safer. Training helps your team follow safety rules and make fewer mistakes. Here’s how training helps:

Benefit | Description |

|---|---|

Improved Operational Efficiency | Trained staff work quickly and do things right. |

Safety Procedures | Training lowers the chance of accidents. |

Legal Compliance | Following rules keeps you out of trouble. |

Accurate Inventory Management | Fewer mistakes mean less lost stock. |

Customer Satisfaction | Orders go out on time, so customers are happy. |

Adaptation to Changes | Training helps your team handle new tools or busy times. |

Employee Morale | Learning new skills keeps your team excited. |

Keep training fun and fresh. Your team will like it!

Workflow Adjustments

You can make your warehouse run better by checking your workflow often. Find slow spots and fix them. Set up clear steps for each job so everyone knows what to do. Review your numbers to see what works and what needs to change. Try these ideas:

Use data to find and fix slow spots.

Make clear steps for every job.

Check your progress with regular reviews.

Try new tools or automation to speed things up.

If you keep improving your workflow, your warehouse works better and your business grows.

Reviewing and Extending Free Storage

If you want your warehouse to work well, you must watch your storage. Maximizing free storage is more than just saving money. It also helps your warehouse run better and helps your business grow. Let’s see how you can check your storage, add more storage time, and change your plans for better warehouse optimization.

Monitoring Storage Usage

You should know how much space you use and how long items stay. Fishgoo’s online dashboard makes this simple. You can see your storage use, check days left, and get alerts before your free period ends. This helps you skip extra fees and plan shipments better.

Here are some smart ways to watch your storage and costs:

Use a warehouse management system to track inventory in real time. You always know what is in stock and where it is.

Teach your team to use the system well. This keeps records right and work smooth.

Do regular quality control checks. You find problems early and keep products in good shape.

Tag your items or orders. This shows which products use the most space or cost the most to store.

Set up alerts for storage limits. You can act fast and avoid overflow fees.

Tip: Check your storage dashboard every week. You will spot trends and fix issues before they get big.

Some companies use special tools to track resource use and costs. For example, they might set approval steps for extra storage or use tags to see which department uses the most space. This kind of warehouse optimization keeps your budget safe.

Extending Storage Periods

Sometimes you need more time than the free storage period gives. Fishgoo gives you 100 days of free storage, but you can add more if needed. Go to the Warehouse section, find your item, and click “Storage Extension.” You can add more days for a small fee.

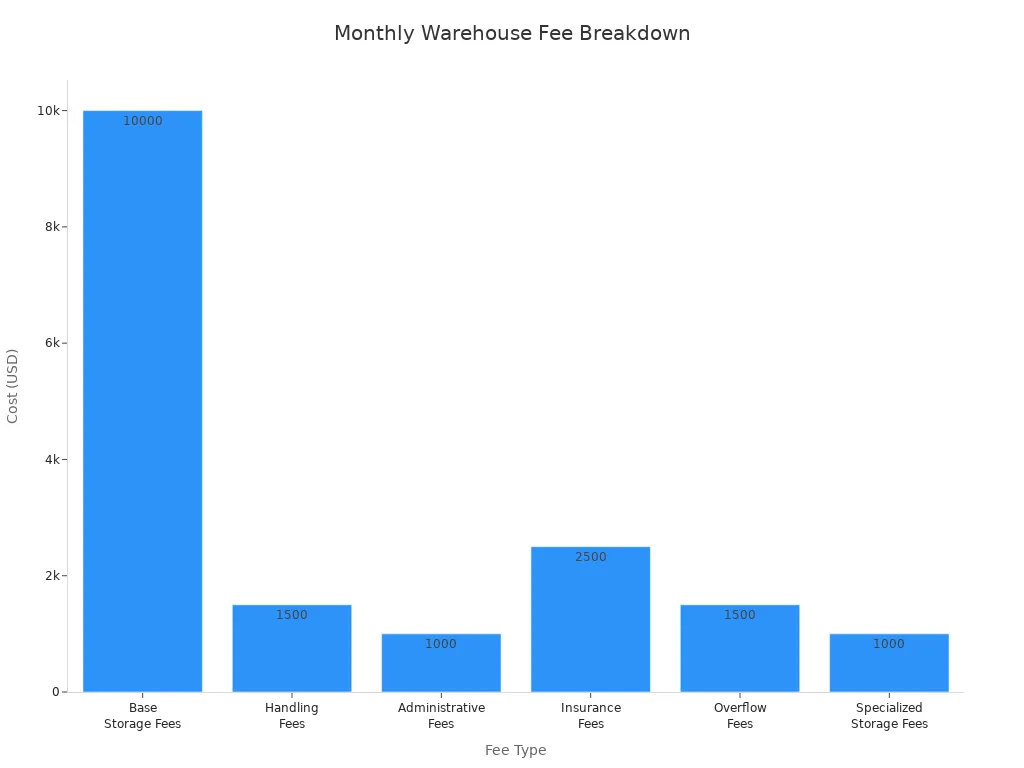

Here’s how the costs usually break down for warehouse storage extensions:

Fee Type | Description | Example Cost |

|---|---|---|

Base Storage Fees | Monthly charge for the space your goods use | $10,000 |

Handling Fees | Charges for receiving and processing your inventory | $1,500 |

Administrative Fees | Costs for account management and paperwork | $1,000 |

Insurance Fees | Coverage for your stored goods | $2,500 |

Overflow Fees | Extra charges if you use more space than planned | $1,500 |

Specialized Storage Fees | Extra costs for items needing special care | $1,000 |

Total Monthly Cost | All fees added up | $29,500 |

Fishgoo’s extension fee is easy: 10 CNY for every 30 days, up to 180 days. You only pay for what you use. This makes maximizing free storage and managing your warehouse simple.

Note: Always check the rules for storage extensions. Some warehouses have limits or special fees for certain products.

Adjusting Strategies

If you often need more storage, you should change your plan. Warehouse optimization means using your space and time in the best way. You can store more and spend less by making a few changes.

Here are some strategies you can try:

Check your product catalog often. Remove items that do not sell well to free up space.

Use vertical racks and high shelves to store more without a bigger warehouse.

Try automation, like automated storage and retrieval systems, to move goods faster and lower labor costs.

Place your inventory using real-time data. Move fast-selling items closer to shipping.

Use modular shelving. You can change your setup as your needs grow.

Adjust your inventory based on demand. Do not keep too much slow-moving stock.

Strategy | Description |

|---|---|

Optimize Space Utilization | Use high-bay racking and automated systems to store more in less space. |

Implement Automation | Add systems like AS/RS to speed up work and lower labor costs. |

Dynamic Inventory Management | Move items around based on sales data to avoid running out or having too much. |

Callout: Maximizing free storage is not just about waiting longer. It is about using every inch of your warehouse and every day of your storage period to help your business grow.

When you keep checking your storage and changing your plans, you get the most from your warehouse. You save money, store more, and keep your business running well. That is real warehouse optimization!

You can make the most of free storage by using smart warehouse optimization. Fishgoo’s tools help you track storage, add more time, and keep things running well. When you focus on warehouse optimization, you save money, work faster, and make customers happy. Here are some clear benefits:

Benefit | Description |

|---|---|

Improved Performance | Warehouse jobs get done better and faster |

Increased Productivity | You get more work done with good storage plans |

Better Forecasting | You can guess inventory needs more correctly |

Reduced Fulfillment Times | Orders get packed and shipped out more quickly |

Decreased Injury Risks | The warehouse is safer for everyone |

Are you ready to begin? Use this checklist to help with storage and warehouse optimization:

Do a full check of your warehouse

Make goals you can measure and reach

Look at how you use space and plan better

Use technology and machines to help

Keep track of your inventory the smart way

Change your warehouse setup if needed

Find better ways to store your items

Teach and involve your team

Watch your progress and make changes

Take some time to look at how you store things now. Try these warehouse optimization ideas and Fishgoo’s tools to help your warehouse work better for you.

FAQ

How do I check how many free storage days I have left?

You can log in to your account and visit the warehouse dashboard. The system shows your remaining free storage days for each item. You get alerts before your free period ends.

Can I extend my free storage period if I need more time?

Yes, you can. Just go to the warehouse section, select your item, and click “Storage Extension.” You pay a small fee for each extra 30 days you need.

What happens if I don’t ship my items before the free storage ends?

You pay a storage fee for each item that stays past the free period. The system sends you reminders so you can avoid extra charges.

Does Fishgoo help with packaging and consolidation?

Absolutely! Fishgoo offers value-added packaging and parcel consolidation. You can combine items for safer shipping and lower costs.

Is my inventory safe while stored in the warehouse?

Your items stay secure in the warehouse. Fishgoo provides quality checks and safe handling. You can request QC photos to see your products before shipping.

See Also

Enhancing Savings Through FISHGOO Package Integration Strategies

Strategies to Streamline Cross-Border E-Commerce Logistics Effectively

Understanding Warehouse Services: Functions and Operational Insights

The Importance of International Warehouse Services for Business Growth

Comprehensive Overview of JD Purchasing and Forwarding Services